|

| Reviews and Templates for Expression We |

NZ's first PET plastic processing plant opens

An old biscuit factory has become home to the country's first PET recycling plant, saving more than 200 million plastic bottles from the tip.

Packaging company Flight Plastics opened the facility on August 2 at the site of the former Griffin's factory in Lower Hutt.

It is the only plant in New Zealand capable of processing polyethylene terephthalate (PET) - a plastic commonly used to make bottles and fruit punnets.

Flight Plastics chief executive Keith Smith with a handful of processed PET flakes and a fruit punnet made of recycled material.

Director Derek Lander said the $12 million project was a huge leap forward for recycling in New Zealand.

It meant PET would no longer have to be sent to China or Australia to be processed and less of the material would need to be imported back into New Zealand for manufacturing.

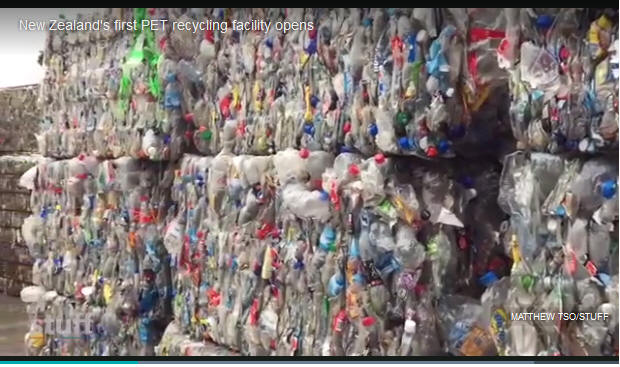

Bales of PET would be bought from collection companies, hen washed and flaked before being turned back into packaging at the Lower Hutt site.

The packaging would be made of about 88 per cent recycled material and was fully recyclable.

New Zealand imports about 20,000 tonnes of PET, but only recycles about 8000 tonnes.

The Flight facility would only be recycling clear plastic which made up 5000-6000 tonnes of the PET recycled in New Zealand - the equivalent of about 200 million plastic bottles. Lander said the facility had been built to handle higher volumes in the future.

Flight received a $4 million grant from the Government's Waste Minimisation Fund which promotes waste reduction and recycling.

"It's nice to be part of the solution," Lander said.

The opening of the facility was timely as China recently announced a ban on the import of waste and recycling from other countries including New Zealand.

That meant New Zealand would have to look for alternative or domestic solutions to dispose of and recycle waste.

While Flight's facility was a step in the right direction, another producer said it was still not economical to install similar infrastructure for other types of plastics.

Carl Longstaff is the managing director of Metal Art, a company which designs products made from recycled soft plastics, including plastic bags processed and produced in Australia.

He said it made sense for companies like Flight to invest in the infrastructure because they already had an established market.

The Waste Minimisation Fund was a positive scheme as a means of encouraging business and better waste management.

"I'd do it tomorrow if we had the market."

|

|

|

|

Copyright remains with the original authors |