|

| Reviews and Templates for Expression We |

Energy Harvesting Wireless Solutions: Building Management and Beyond

The intelligent control of buildings requires sensors to collect relevant data from several points of measurement, and controllers to process the information. The sensor networks in medium to larger facilities may be comprised of hundreds to thousands of these sensory nodes, all requiring power and communication capability. At the same time, the solutions should be easy to install with a fast return on investment, providing significant energy savings and increased comfort.

These requirements are met by energy harvesting wireless solutions, now an established IEC standard, controlling sustainable buildings for the past ten years. By employing energy harvesting, the wireless modules generate their power from the environment and therefore work without batteries. A variety of energy sources can be utilized; an electro-dynamic energy converter uses mechanical motion, a miniaturized solar module generates energy from light, and a thermoelectric harvester with a DC/DC booster converts temperature differential as an energy source.

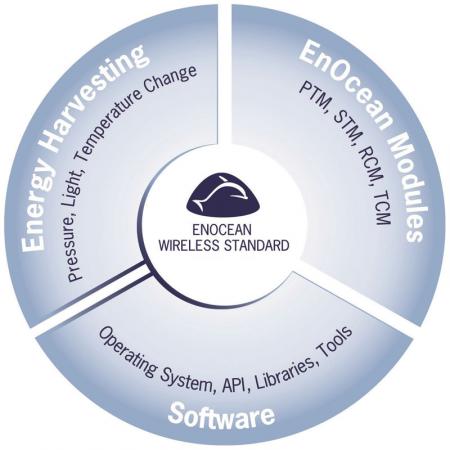

These highly efficient harvesters generate sufficient energy to power sensors, analyze environmental conditions and then transmit a wireless signal. This includes switches, door/window contacts along with temperature, humidity, occupancy and light sensors, communicating with intelligent controllers and building automation systems. The energy harvesting wireless technology is composed of three major components that are optimally matched to each other: micro energy converters, ultra-low-power electronics and an optimized wireless standard. This comes along with software tools that allow a user-friendly integration in applications (Figure 1).

Figure 1

The three components of energy harvesting wireless technology.

Optimized for Building Automation

For architects, facility managers or installers, the self-powered technology offers several benefits in a building automation system. Being wireless, the sensors and switches can be flexibly located to optimize effectiveness. If an office layout changes, the sensors can simply be removed and repositioned at any time. The radio communication is optimized for range and reliability, communicating through common home and office walls at a distance of up to 90 feet. But the actual highlight is the devices’ batteryless characteristic, making them maintenance-free. There are no power wires to pull, nor batteries to replace and dispose of properly. This yields to a low-cost, reliable system leveraging an environmentally friendly technology (Figure 2).

Figure 2

The technology’s flexibility allows positioning the batteryless sensors at any place of optimal measurement and data collection. Gateways can translate the energy-optimized radio protocol to other wireless standards or networks.

Further Development for New Applications

Energy harvesting technology is just getting started. When we take a look beyond building automation, new application fields for self-powered wireless communication arise, including structural health monitoring, water quality control and forest fire prevention or smart city management.

For such applications, mainly outside the building, the components of energy harvesting wireless technology, consisting of energy converters, wireless transmitters, energy management, software and development tools as well as the energy-saving radio protocol, need to be further enhanced.

The next generation of energy harvesting radio technology will enable up to ten times longer radio ranges to wirelessly transmit data over a distance of more than 1.7 miles, enabling new outdoor applications with higher range requirements. The increased energy need of such a long distance can be realized by the progress of other components, such as energy harvesters.

Motion is a stable and reliable energy source that can be harvested almost anywhere, for example in the movement of doors, windows or machine components, and in the vibration of motors, the rotation of door handles or switches. New types of mechanical energy harvesters will make use of the energy of flowing gases and liquids in particular. These harvesters will be used to power metering applications and help eliminate batteries from millions of these devices.

A second energy source, light, will play a significant role as future generations of miniaturized solar cells will combine reduced energy consumption with improved energy generation under low light conditions. While the limit of operation is light intensity of about 100 lux at 5% efficiency today, next generation solar cells based on organic material or dye-sensitized technology can operate down to 10 lux light intensity with more than 10% efficiency.

Finally, temperature differentials contain significant energy and are therefore ideally suited to powering devices. The cooling of just one drop of water by 1 degree Celsius releases energy for about 25,000 energy harvesting wireless telegrams. These harvesters will allow very robust sensor nodes, independent of light and therefore not sensitive to dirt.

Another contribution to the energy balance is reducing energy consumption. As the energy demand of sensor modules gets lower from generation to generation, the technologies’ suitability is enhanced. In addition, there are significant improvements in energy storage components. The target is to store sufficient harvested energy to operate weeks to several months and up to a year without additional energy.

Next Decade of Internet

With IPv6 providing an almost unlimited number of IP addresses, machines (sensors, actuators, controllers) interacting directly with other machines on a broad scale will grow rapidly. Thus the Internet of Things (IoT).

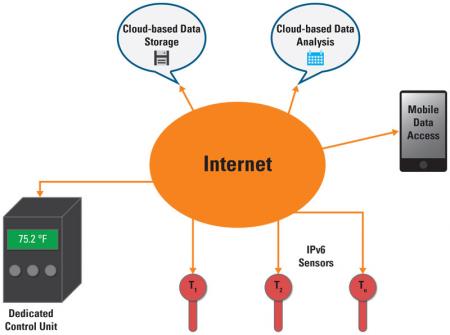

Having a large network of sensors, actuators and control units interacting with each other and the user can bring several distinct benefits. More sensor data provides better insight for the control system. Unlike the standard approach of one or more sensors being connected to one central control unit, an Internet of Things allows the sharing and reuse of available information between different nodes. Thus, the system collects data only once but uses the information for several applications (Figure 3).

Figure 3

Batteryless sensors connected to the Internet not only deliver information for a local unit. The data stored in the cloud rather can be the basis for several analyses and therefore reused for different purposes.

Current control systems are usually local; for example sensors, control unit and actuators are often in close proximity and wired or wireless, directly connected with each other. IPv6 connectivity no longer requires such proximity. It allows centralized, or even outsourced computing resources (Cloud-based computing), thus driving down infrastructure cost. Besides this, the IoT allows dynamic creation of control networks. The networks can be formed or dissolved dynamically based on time, location or other parameters. For instance, cars could automatically query temperature sensors in the street to determine if there is a danger of ice on the roads and warn the driver accordingly. These examples illustrate the enormous potential that can be unleashed by an Internet of Things.

All required base technologies for forming such a network already exist today—sensors, actuators, local or Cloud-based control units and IPv6 to connect all of them together. Nevertheless, the energy harvesting sensors themselves cannot communicate directly over IP. Batteryless wireless transmission means that the chosen protocol must be optimized for ultra-low-power communication. The payload associated with sensors is small (a few bytes), therefore the protocol overhead must also be limited as much as possible.

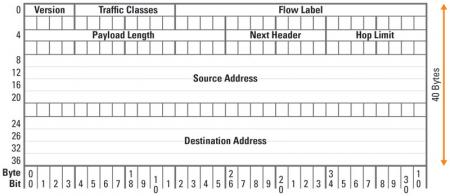

Employing IPv6 as the communication protocol at the individual sensor level is challenging because it includes significant overhead, as the IPv6 header alone requires 40 bytes of protocol data (Figure 4).

Figure 4

The IPv6 header requires 40 bytes of protocol data.

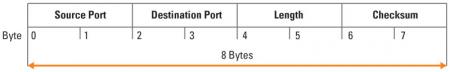

In addition to that, UDP, probably the simplest communication protocol on top of IPv6, would require an additional 8 bytes of protocol data. Based on the IPv6 and UDP header structure, the transmission of 1 byte sensor data would require an additional 48 bytes of low-level protocol data. IPv6/UDP is therefore not well-suited for energy-efficient communication on the sensor level in a network (Figure 5).

Figure 5

The UDP header on top of IPv6 comes with 8 bytes of protocol data. This causes a bandwith-intensive data transfer which needs a lot of power. Therefore, batteryless sensors are not suitable to directly communicate via IPv6.

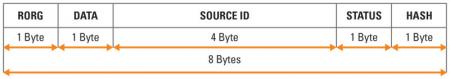

In comparison, the EnOcean protocol for energy harvesting wireless applications only incurs 7 bytes of protocol overhead for the transmission of 1 byte of sensor data (Figure 6).

Figure 6

The energy harvesting wireless protocol is particularly optimized for an ultra-low power communication, requiring only 7 bytes of protocol data.

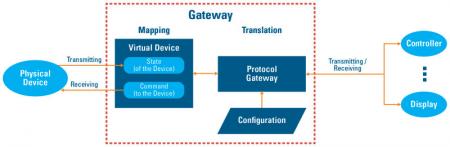

Translation of data between such an energy-efficient sensor protocol and IPv6 is provided by dedicated IP gateways that represent the state of each connected sensor node and act as their representative within the IPv6 network. This approach allows exchanging data with individual sensors even while they are sleeping and therefore unavailable for direct communication. Upon wake-up, sensors will then update their state information in the gateway and retrieve messages/commands intended for them (Figure 7).

Figure 7

Gateways that reproduce a sensor’s state allows data translation in real-time even when the self-powered sensor is only active in specific wake-up cycles.

Sensory Organs for Worldwide Use

With the technology’s progress and the enhanced abilities of IPv6, new application fields for energy harvesting wireless communication become feasible. Finally, let’s take a look at how enhanced batteryless technology and IPv6 communication will turn the Internet of Things into reality.

Cloud-based computing resources could be used to combine local temperature data provided from batteryless sensors with an external weather forecast to compute the exact amount of water required for agricultural irrigation. This information would then be sent to a remote actuator controlling the water flow. Similar sensors could measure the degree of humidity or soil nutrients for an optimal supply of water and care for plants.

Self-powered wireless sensors could also be placed over large areas to provide early warnings or to monitor farm animals and plants in order to react very quickly to changing conditions. Temperature sensors, for instance, could send position data and an alarm signal when they measure the heat of a fire. Via a central gateway, a notification is immediately sent to the nearest fire station and/or via SMS to a responsible person’s smartphone. Such an early warning system could prevent the spread of forest fires.

Whether it is water, gas or oil—all resources on earth are limited and therefore need to be protected and used carefully. Batteryless sensor networks can support this by providing the needed data to monitor water in terms of quantity and quality, or the movement of shoals of fish. In addition, detectors can use miniaturized solar cells or motion energy converters to power wireless signals that report water, oil or gas leaks to a gateway controller or directly to a valve. The energy harvesting technology prevents system malfunctions that otherwise could be caused by battery failures.

The fabric built of large structures including bridges, tunnels, dams or drilling platforms has to resist extreme forces like weather, earthquakes or traffic. Today, in the U.S. alone, nearly 25% of all bridges are deemed structurally deficient or functionally obsolete. In numbers, that is more than 150,000 bridges. Radio sensors, powered by light, temperature changes or vibrations that permanently monitor critical parameters, can warn against non-conformance and prevent breakdowns. These sensors would monitor parameters related to structural health, such as integrity, position and vibrations, and act as an early warning system. A similar functionality can provide an alert in the event of an avalanche or rock fall.

By 2030, 60% of people will live in a city—representing almost six billion people. Intelligent control will be needed to coordinate people’s daily lives and prevent a city from collapsing into turmoil. This includes automated control of traffic, street lights, energy supply and transportation of goods as well as waste disposal. This can only be realized with millions of self-powered sensor nodes collecting and delivering the necessary data. Malfunctions of battery-powered sensors could cause chaos in such a deeply connected system. But cables are no alternative either, as they are too complex and costly to install. In contrast, energy harvesting-powered devices can overcome both issues. Solar-powered occupancy sensors, for example, notify when somebody is walking on a street and send a signal to activate the street light. The same can function with motion-powered sensors in the streets’ surface when a vehicle passes. Other fields of application are cold chain monitoring for food transportation, or the notification and automated repeat order when goods in a store run out.

Another wide field of application is making our life easier, more secure and comfortable. The demographic change necessitates modern technology for the elderly, when it comes to being able to live at home independently for as long as possible or if sickness occurs. Ambient assisted living systems can provide data on a tenant’s activities and send a notification to a caregiver or relative if there is a remarkable change in daily routines or too little activity. Alarm systems such as portable emergency buttons complement the system. In regards to flexibility and low maintenance effort, the common requirement for all components is to be wireless and batteryless.

|

|

|

|

Copyright 2011 Energy and Technical Services Ltd. All Rights Reserved. Energyts.com |