|

| Reviews and Templates for Expression We |

7 steps to effective energy management

In a global economy, sustainability has become an essential part of business strategy. Leading organizations worldwide understand that sustainability is a key factor in lowering costs, opening new markets and driving efficiency and innovation throughout an organization. A cornerstone of sustainability is pollution prevention, or P2. Through the effective implementation of P2 and Energy Efficiency (E2) strategies, businesses can incorporate sustainability into day-to-day operations in ways that promote long-term cost savings and improved environmental performance.

Successful implementation of pollution-prevention and energy-efficiency initiatives are often a direct result of an organization's ability to identify and assimilate relative information, recognize the relationship of environmental performance to the business model and focus existing systems and resources towards specific goals. The full support of management is essential in planning, structuring and implementing sustainability efforts within a business framework.

Organizations must have both the ability and the desire to systematically implement pollution-prevention and energy-efficiency opportunities into business operations. An organization that is committed to achieving P2 and E2 outcomes will need to integrate into its day-to-day operations strategies that include eliminating or reducing pollution at its source.

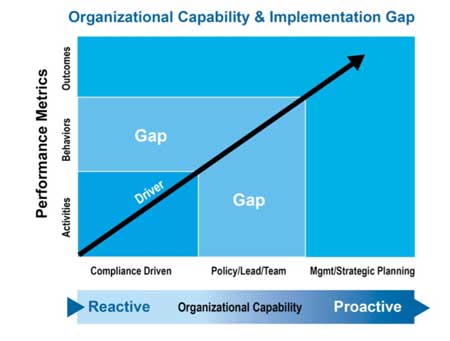

An organization's ability to achieve improved environmental performance often directly relates to whether its management is reactive or proactive. A reactive organization is typically driven primarily by regulatory compliance or by trying to correct problems that could have been prevented through proactive planning. A proactive organization is driven by strategic planning and long-term commitments to improving its operations.

Whether a business operates in a reactive or proactive manner is an indicator of organizational capability. The more proactive a company is, the better positioned it will be to respond effectively to implementing P2 opportunities and achieving sustainable practices. Strategic planning and effective management systems are key elements of a proactive organization.

The Implementation Gap

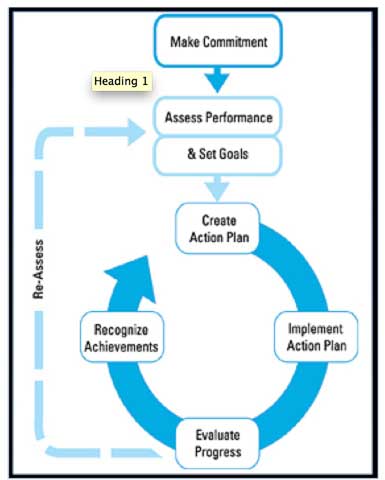

Organizations that resist change make implementation of pollution prevention and energy management opportunities a challenge. By adopting a systematic approach, such as the Energy Star Seven-Step Process, organizations that struggle to overcome built-in barriers and a lack of basic knowledge about sustainability strategies can begin to plan and implement a successful program through an established process. By making a commitment to improved environmental performance, assigning a leader and assembling a team, organizations can establish and strengthen behaviors to achieve long-term success with sustainability efforts.

Organizations that resist change make implementation of pollution prevention and energy management opportunities a challenge. By adopting a systematic approach, such as the Energy Star Seven-Step Process, organizations that struggle to overcome built-in barriers and a lack of basic knowledge about sustainability strategies can begin to plan and implement a successful program through an established process. By making a commitment to improved environmental performance, assigning a leader and assembling a team, organizations can establish and strengthen behaviors to achieve long-term success with sustainability efforts.

The framework of the Energy Star Seven-Step Guidelines for Energy Management has been proven to be an effective way for organizations to systematically get to P2 and E2 outcomes.

7 steps for effective energy management

-

Make the Commitment. The commitment to continual improvement is the most critical step to overcoming the P2 implementation gap. Achieving P2 and E2 implementation success through the seven-step process requires top level support communicated by an environmental and energy management policy, by establishing a cross-functional team representing the administrative and process knowledge of the organization, and by appointing a leader to ensure continuity of focus, communications and effort. An engaged team effort supported by management as a critical business strategy will ensure the ability of a company to identify and achieve P2 an E2 outcomes.

-

Assess Performance and Opportunities. Identifying environmental performance opportunities begins with understanding current and past waste generation and energy use. A cross-functional team-based assessment that evaluates performance, systems and equipment will leverage the intellectual capital of an organization and allow it to recognize improvement opportunities from many perspectives. Conversations with staff at the operational level can lead to “ah-ha” moments that can solve problems and find creative solutions. Assessing environmental performance based on analyzing collected data and establishing baselines to measure progress while using the knowledge base of the organization will create new ways of seeing the business opportunities that P2 and E2 can provide.

-

Set Performance Goals. Setting aggressive but realistic goals for improving environmental performance will drive activities that get to successful outcomes. This step provides a common view of improvement throughout the organization while capturing the commitment to reducing pollution and energy usage. Performance goals help to monitor the success of the environmental and/or energy management program by identifying specific areas of progress and setbacks. Effective goals will determine the scope and estimate the potential for improvement.

-

Create an Action Plan. An action plan serves as a blueprint to guide and monitor the systematic approach to improved environmental performance. It provides focus for the team by indicating the scope and scale of goals, targets, roles and resources. To promote success, the plan should be accepted by all areas of the facility that it addresses.

-

Implement the Action Plan. Elements critical to successfully implementing the action plan include creating a communication plan, raising awareness, building capacity, motivating staff, and tracking and monitoring progress.Communicating the action plan is critical and will require an overarching message about mission, policies and progress. While the communication plan serves to raise awareness about energy efficiency and environmental sustainability, employees, customers and the community should also be educated on how they can contribute to improved environmental performance. Identifying training needs can also contribute to successfully implementing pollution prevention and energy efficiency opportunities. Continual feedback on successes achieved can help motivate employees to continually improve.

-

Evaluate Progress. Periodic evaluation of the action plan will keep the team informed about progress made on established environmental performance improvement goals. Reviewing the action plan will further identify any efficiency measures that should be modified or added.

- Recognize Achievements. Once the momentum of achieving pollution prevention and energy efficiency outcomes has been established, it is important to keep it going. The commitment to continual improvement needs to be maintained over time for the seven-step process to be successful. A committed leader to drive the process and a motivated team to carry it out provides the best opportunity for a long-term program that achieves results.

Recognizing achievements will help maintain the momentum of your environmental improvement initiatives. The most successful programs include both internal and external recognition. Internal recognition of staff and team members connects their efforts directly to the success of the program and provides motivation for the staff. External recognition, such as press releases and community outreach, provide positive public relations opportunities for the organization which can mean improved brand loyalty and acknowledgement as an environmentally responsible organization. A company that has a positive environmental reputation has a competitive advantage.

Is your organization ready?

P2 technical assistance providers in your state, like KPPC – Kentucky Pollution Prevention Center, may provide assistance with finding environmental sustainability opportunities for your organization. Additional P2 and E2 information and tools are available online through the P2Rx network, on EPA's website and on the KPPC – Kentucky Pollution Prevention Center website.

|

|

|

|

Copyright 2011 Energy and Technical Services Ltd. All Rights Reserved. Energyts.com |