|

| Reviews and Templates for Expression We |

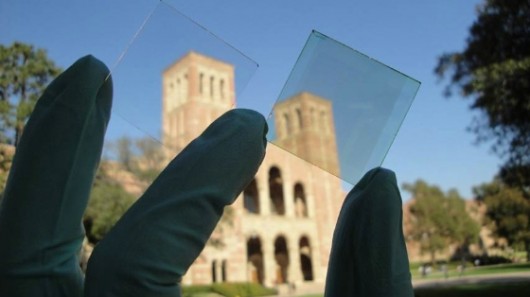

UCLA produces transparent solar cells that harness infrared light

A UCLA team has developed a new type of solar cell that is nearly 70 percent transparent to the naked eye. The plastic cells, which use infrared instead of visible light, are also more economical than other types of cells because they are made by an inexpensive polymer solution process and nanowire technology, potentially paving the way for cheaper solar windows.

Solar panels are great. The only problem is that they take up quite a bit of space. To run a building off of solar panels you’d pretty much have to cover it with them. Since people like things called “windows,” that’s usually not an option. Even running small devices off the sun is a bother since the panels are often bulky, take up areas wanted for other purposes or need to be placed somewhere really inconvenient, like the back of a phone. If only solar cells were thin films that you could see through, then you could turn windows and tablet displays into solar panels.

We’ve looked at the idea of transparent solar panels before, but most solutions until now have been only “sort of” transparent with wires or beads embedded in or coated on glass. True, they let light through, but since the opaque components need to absorb some light to generate power, the effect is a bit like tinted glass. They also tend to be a bit on the expensive side.

Enter Yang Yang, a UCLA professor of materials science and engineering and director of the Nano Renewable Energy Center at the California NanoSystems Institute (CNSI). He and his team have developed a new Polymer Solar Cell (PSC). This photoactive plastic acts as a high-performance transparent solar cell that lets in a much higher percentage of light. The reason is that the PSC doesn’t generate power from visible light. Instead, it absorbs invisible infrared light and converts that into electricity. This means that the cell is 70 percent transparent to the eye.

Another advantage of the PSC is that it’s made using a solution process that Yang has been improving upon since 2009. In this process, the PSC is formed by dissolving the near-infrared light-sensitive polymer in a solvent, applying it to the film base and then baking it. The cost is further brought down and the transparency improved by replacing metal conductors with silver nanowire and titanium dioxide nanoparticles. The result is a near-transparent photoactive film that is four percent effective.

According to Yang, "these results open the potential for visibly transparent polymer solar cells as add-on components of portable electronics, smart windows and building-integrated photovoltaics and in other applications. Our new PSCs are made from plastic-like materials and are lightweight and flexible. More importantly, they can be produced in high volume at low cost."

If the PSC or some variant proves successful, it may mean that one day we’ll see skyscrapers making their own power from their vast curtains of windows, self-powering smartphones that look like slabs of glass and maybe even solar powered glass patio tables.

|

|

|

|

Copyright 2011 Energy and Technical Services Ltd. All Rights Reserved. Energyts.com |