|

| Reviews and Templates for Expression We |

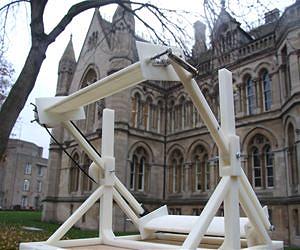

New style turbine to harvest wind energy

a specialist research assistant to help Wind Power Innovations with design and development of the frame, rotating base, swinging arms, aerofoils, the generator and the outer housing of the system.

a specialist research assistant to help Wind Power Innovations with design and development of the frame, rotating base, swinging arms, aerofoils, the generator and the outer housing of the system.

Future Factory, the university's sustainable design project, is helping Heath Evdemon, founder of Wind Power Innovations Ltd, to progress the first technology demonstrator of the Wind Harvester - a small system capable of generating power from a range of wind speeds. With blades of initially just one metre, the Wind Harvester has potential for both commercial and domestic use.

Traditional wind turbines typically have three blades which rotate around a horizontal hub at the top of a steel tower. Most generate maximum output at an approximate wind speed of 30mph and shut down to prevent storm damage at 50mph or above, causing reduced efficiency of some turbines.

The new Wind Harvester is based on a reciprocating motion that uses horizontal aerofoils similar to those used on aeroplanes. It is virtually noise-free and can generate electricity at a low speed, which may result in less opposition to new installations. It will also be operational at higher wind speeds than current wind turbines.

It can be made in any size up to approximately 15 metres across and only needs to be approximately half a metre off the ground in prominent positions such as on hills and hillsides; rock outcrops; and on domestic, farm and industrial buildings and structures.

All sizes can be broken down into handleable pieces so installation will not require the use of heavy machinery, which is particularly relevant to environmentally sensitive areas.

In order to take the Wind Harvester from its current prototype stage to a fully working model, Future Factory has funded a specialist research assistant to help Wind Power Innovations with design and development of the frame, rotating base, swinging arms, aerofoils, the generator and the outer housing of the system.

The company will also receive support from Dr Amin Al-Habaibeh, reader in advanced design and manufacturing technologies at the university's School of Architecture, Design and the Built Environment.

Along with funding from Future Factory, the company has also received Pounds 28,000 from the Peak District National Park's Sustainable Development Fund and Pounds 3,000 from the Live and Work Rural programme. A large scale demonstrator is expected to be installed in the national park once it has been completed by the team.

Dr Amin Al-Habaibeh said: "Nottingham Trent University is a leading university in sustainability and renewable energy. This project is an opportunity to develop the technology further for commercialisation so that the Wind Harvester can be used in locations where it is difficult to install current wind turbine farms."

Heath Evdemon said: "I first had the idea for the Wind Harvester six years ago but I put it on the back burner at that time. It wasn't until I met the Future Factory team that I knew it could become a reality and their enthusiasm and support has been invaluable.

"We're looking for potential sites within the Peak District National Park at the moment and then we'll turn our attention to industry, but it's a product which could one day be rolled out to farms working towards becoming carbon neutral and homeowners looking for a cheap and sustainable source of power."

Debra Easter, Future Factory project manager, said: "Nottingham Trent University is ranked as the UK's greenest university in the People and Planet Green League and it is projects such as this that reaffirm our commitment to the environment. We're very excited to be helping Heath realise his dream and potentially change the face of wind power."

|

|

|

|

Copyright 2011 Energy and Technical Services Ltd. All Rights Reserved. Energyts.com |