|

| Reviews and Templates for Expression We |

What's the Greenest Way to Dry Your Hands?

Editor's Note: This article, originally published on November 15, 2011, was updated today with a response from Kimberly-Clark Professional.

It's a question that bedevils facility managers. What's the most environmentally conscious and cost effective way for people to dry their hands in company and public restrooms?

Paper towels made from recycled content? Electric hand dryers? Cotton towels that need to be laundered?

Dyson, the maker of the cold air-driven hand dryers, contends its Airblade is the best option when it comes to energy efficiency and commissioned a study by the Massachusetts Institute of Technology to look into the matter.

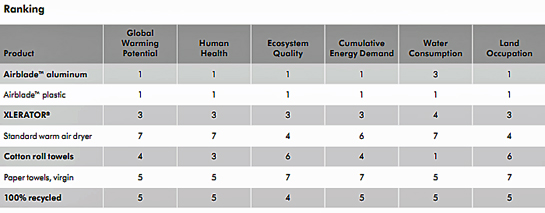

Researchers at MIT's Material Systems Laboratory conducted life cycle assessments on the use of paper towels made from 100 percent recycled content, paper towels made of 100 percent virgin content, cotton towels on a roll (the kind on a spindle), a generic warm-air dryer, an XLERATOR hand dryer by Excel, and two Dyson Airblade models, one with a plastic cover and one with an aluminum cover.

While Dyson asserts that the study and its findings are the results of an independent process, it's not surprising that Dyson came out on top. [The Carbon Trust conducted a case study of the Airblade's carbon footprint earlier this year and found that it used about 80 percent less energy than conventional hand dryers.]

What is surprising is that other methods -- even use of paper towels -- fared so poorly in the life cycle assessment. Here's what the executive summary of the MIT study said:

"Paper towels and standard warm air dryers were the two worst performing type of hand drying system in terms of environmental impact. For paper towels the majority of the impact comes from the production of the paper towels themselves. The paper towel packaging, dispensers, waste bins, and bin liners account for less than 10 percent of the environmental burden. For standard warm air dryers, the majority of the impact comes from the use phase; with the longer dry time and higher rated power of the machine contributing to the majority of the GWP impact.

"...For Dyson Airblade hand dryers, the majority of impact comes from the use phase; with its shorter dry time contributing to its lower impact ..."

Here is a chart from the study that ranks the impacts of the seven hand drying methods. The higher the number, the greater the impact.

The researchers acknowledged that several LCA studies have been commissioned by other product manufacturers. But, they said, "[b]etween all these studies, there is not a single unified approach that can be used to examine all seven hand drying methods. Because of each of the studies' differing functional units, assumptions, data, and life cycle assessment outcomes, each product type cannot be easily compared. This LCA study was commissioned as a means of addressing this gap."

In contrast, Excel has said that an LCA conducted by Quantis in 2009 found that the XLERATOR reduced the carbon footprint of hand drying by 50 to 75 percent compared to other traditional hand dryers and recycled and virgin content paper towels. The manufacturer also says its product uses 80 percent less energy than conventional dryers and pencils out to a 95 percent cost savings over paper products.

We reached out to a couple of those big-name paper product makers and if we hear back, we'll add their comments.

Update: November 18, 2011:

In response to our query, we heard from Kimberly-Clark Professional today, which takes issue with the report. Here's the statement from the Kimberly-Clark division that works with corporate customers:

Kimberly-Clark Professional has seen the MIT study that Dyson commissioned, and we are currently examining it in greater detail. We value the insights that a well-structured and executed life cycle analysis can provide. Upon initial review, we believe this LCA missed the larger issue and primary purpose of hand washing as it only compares the environmental impact of hand drying methods while failing to address the critical impact of hand hygiene.

Our opinion, as well as that of LCA experts and standards, is that studies such as this one (comparative LCA studies) are meant to examine products or services that provide comparable performance and function. That is, they should compare apples to apples. In academic / LCA circles, this is referred to as a "functional unit." In this case, the primary function of air dryers and hand towels differs: While both products dry hands, a critical function of the hand towel is to promote hand hygiene by reducing bacteria, thereby providing healthier environments.

To be fair, the report authors state that "Although hygiene is part of the protocol and is another purpose of the systems that is of interest to the scientific community..., it is not considered in this analysis." This is unfortunate, as other studies have shown that the choice of hand drying method has a significant impact on hand hygiene.

At Kimberly-Clark Professional we are strongly committed to reducing the environmental impact of the paper towels we produce. While we are working hard to reduce that impact throughout our products' life cycles, we are firmly committed to ensuring the health and hygiene benefits to our customers and the quality and performance of our products.BY Leslie Guevarra

|

|

|

|

Copyright 2011 Energy and Technical Services Ltd. All Rights Reserved. Energyts.com |